Strength Testing Time

We have had a number of people asking why our carriers priced as they are when they can buy a cheap Chinese made bag down the road that they think will do the same job. We always tell them “you get what you pay for” and our carriers are made to last. We show them the materials we use and tell them they can safely carry anything they can fit into one of our carriers, but we thought it would be really good to prove it.

So, we looked around the factory and found one of our old prototype Club 500 boat carriers, one of several carriers made to try out different ideas in carrier design and is similar to our production carriers except for a few minor differences in the construction - It is without the lining or the extra over-locking of the corner seams (it only has a single row of stitching), has shorter handles attached with flag stitching (we use a couple of strong bar tacks, made with a bar-tacking machine, for attaching the handles in the production bags - bartacks are used on rock climbing slings, a testament to their strength) and the draw cord eyelets are at the side between the handles instead of at the ends of the bag.

The materials used are the same type as the production carriers, but the carrier was made with an end of roll piece of material where the dying had ended - which accounts for its strange colouring, that and the dirt of a year’s rough use protecting things in the factory from damage...

At the test facility the carrier was loaded up with steel bars in a series of steps, but the testers eventually had to stop at 350Kg (that’s one third of a ton!!) because they couldn’t get any more steel bar weights into the carrier! So we still don’t know the breaking point of the carrier, but you can rest assured that it will carry anything you can get into it (including that full size Harley-Davidson Street Glide touring motorcycle you were thinking of getting!), though you may need to get a forklift truck to move your model if it does weigh a third of a ton...

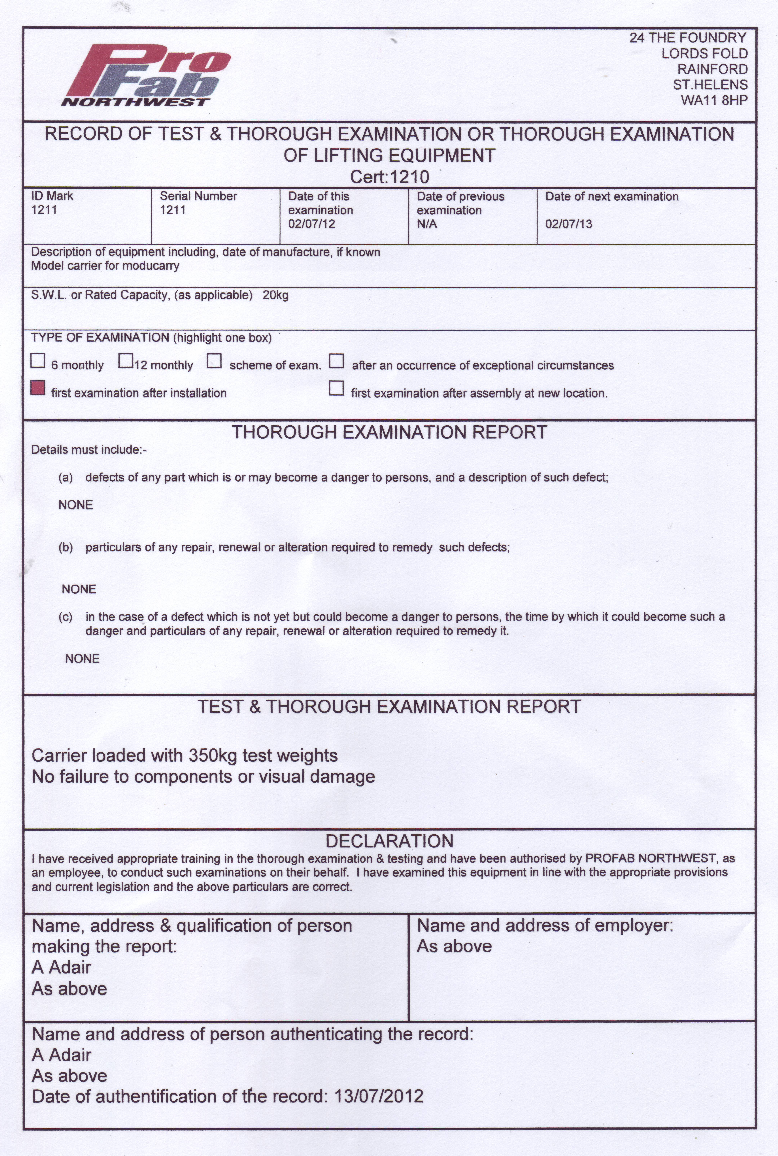

The testers gave us a certificate to confirm the performance and commented that they could not find any visible damage to the carrier – they also said they couldn’t believe the strength of our carriers!

So now we have proof of the actual strength of our carriers, though we really wouldn’t advise trying to lift much over 25kg off the floor and in reality very few models are likely to be over 20kg in weight.

Incidentally, I bought one of the cheap Chinese made bags - intended as aircraft cabin luggage backpacks, with a price of £24.99 on the package but on sale for £9.99. The zip on it opened from the bottom as the stitching stretched at 6Kg spewing all the contents of the pack onto the floor - I keep it now as a comparison to our carriers on our trade stand at shows...

Need we say more?